No Products in Your Cart

Hand-selected by woodworkers

Project-ready quality

You get exactly what you see

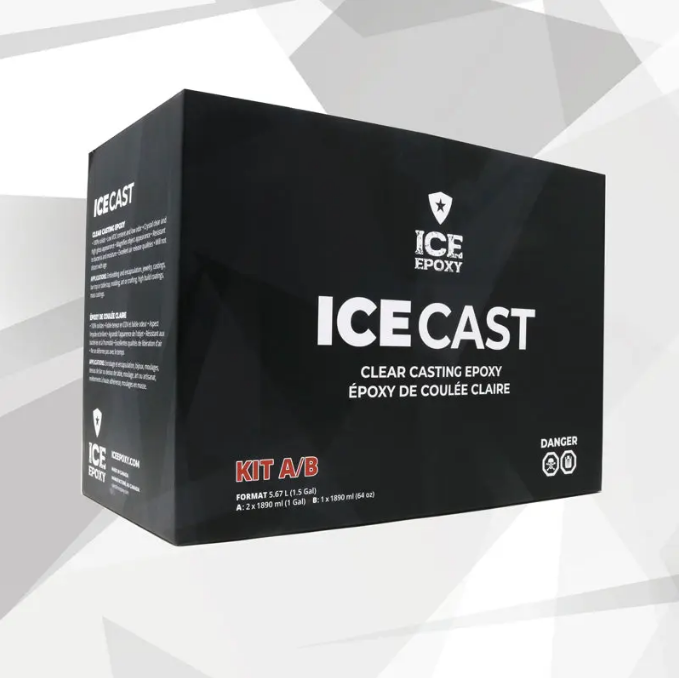

ICE-CAST is a two-component epoxy casting system. It is UV resistant and has anti-yellowing properties, strong adhesion, good fluidity, natural defoaming. It is used for mass castings with thicknesses greater than 1 inch. and up to 4 inches. is designed for casting, potting and embedding applications. The low color and low viscosity allow for bubble free, crystal-clear castings ideal for art and hobby applications. It is formulated for a long gel time, with low exothermic heat buildup. ICECAST has a low VOC content, for user safety and reduced environmental impact.

• 1 to 4 in. deep pour

• Ratio 2A:1B

• UV Resistant

• 100% solids

• Low VOC content and low odour

• Crystal clear and high gloss appearance

• Magnifies object appearance

• Resistant to bacteria and moisture

• Excellent air release qualities

• Will not distort with age

PRIMARY APPLICATIONS

Embedding and encapsulation

Resin jewelry

River castings

Bar top or table top

Molding resin

Art or crafting resin

High build coatings

Mass castings

ICECAST should be stored in a dry place between 59 - 70°F (15 - 21°C), out of the sun and out of reach of children. Resin and hardener should not be left in an open container. Application should be used where humidity is under 60% and temperature is between 59 - 70°F (15 - 21°C) Use a de-humidifier if needed. ICECAST should be used within one year of purchase.

IMPORTANT NOTICE TO PURCHASER: We are not responsible of any damaged, transformation or alteration of the woodwork, table, charcuterie board or any work that is done with our epoxy. The work done is hand crafted with wood or any other material that can vary in form and shape with humidity and temperature and cause a separation or damaged to the epoxy itself and we don’t control those item and or environment. Epoxy has no flexibility and becomes an inert plastic once it’s dry. We don’t warranty the bondage with the wood. The woodworker needs to take all the precaution possible to solidify is work, make sure the humidity of the wood is below 10% and give all the recommendation to the customer in order to keep the table in good condition. There’s no warranty on the UV discolouration of the epoxy. We use UV absorber in order to make the epoxy resist as much as possible to the UV rays.

Not 100% satisfied? We’ll replace it, refund it, or fix it — whatever it takes

From a single standout board to full retail or renovation projects, we’ve helped over 3,000 Canadian woodworkers bring their vision to life.

Whether you’re a first-time DIYer, a contractor building custom interiors, or a designer sourcing unique wood for a client — we have the experience, selection, and support to get you exactly what you need.