No Products in Your Cart

Before your tools ever touch a board, the whole journey starts with a feel for the two big families of wood: hardwoods and softwoods. This is the first and most important fork in the road for any project, and surprisingly, it has more to do with the tree’s biology than its actual toughness.

Choosing the right material isn't about memorizing a bunch of obscure botanical names. It’s about getting a gut feeling for how a piece of wood will behave. The easiest way to wrap your head around the hardwood vs. softwood difference is with a simple analogy.

Picture hardwoods—which come from leafy, deciduous trees like Oak and Maple—as a dense bundle of tiny drinking straws. Their cell structure is complex, packed with small vessels designed to move water. This density is what generally makes them heavier, more durable, and better at shrugging off dents, making them perfect for furniture, flooring, and cutting boards.

Softwoods, on the other hand, come from coniferous trees like Pine and Cedar. Think of their structure more like a honeycomb. It’s a simpler, more uniform design with more air pockets, which makes the wood lighter and often cheaper. That doesn’t mean they're weak; they just play by a different set of rules.

Beyond that initial split, a wood’s most defining feature is its grain. The grain is the unique pattern created by the tree's annual growth rings. This pattern is the wood’s fingerprint, telling you everything about its visual appeal and how it will fight (or cooperate) with your tools.

The way a log is sawn also dramatically changes the look of the board. The angle of the cut in relation to the growth rings creates distinct patterns like plain sawn, quarter sawn, and rift sawn.

Each sawing method doesn't just alter a board's appearance; it also affects its stability and how much it will move with changes in humidity. For a deeper dive into these concepts, you can explore our detailed wood identification guide.

Getting a handle on these basics—hardwood versus softwood and the language of grain—is your first real step. It’s what turns you from someone who just buys lumber into a woodworker who thoughtfully selects the perfect material to bring their vision to life.

Now that we have a feel for the two main families of wood, let's meet the all-stars of the North American workshop. These domestic hardwoods are the workhorses and show ponies you'll turn to again and again. They form the backbone of countless projects, from sturdy furniture built to last for generations to delicate decorative pieces.

Each species has a distinct personality... A unique way of behaving under your tools, and each has a signature look. Getting to know these traits is the key to matching the right material to your vision, ensuring your project not only looks incredible but also performs exactly as it should.

Let's dive into some of the champions you'll find at The Knotty Lumber Co.

Black Walnut is often called the undisputed king of fine furniture wood, and for good reason. Its heartwood has a rich, deep brown colour, sometimes with hints of purple, that comes alive with just a simple oil finish. The grain is usually straight but can feature stunning wavy or curly patterns that add a serious touch of luxury.

With a Janka hardness of 1,010 lbf, it's tough enough for tabletops and chairs yet remains a pleasure to work with. It cuts cleanly, sands to a silky-smooth finish, and takes joinery without much fuss. Finishing is where Walnut truly shines; a clear oil or varnish makes the complex grain pop, creating incredible depth.

For a comprehensive look, our deep dive into Black Walnut lumber covers everything you need to know.

Ambrosia Maple isn't a specific species but rather a stunning variation of Soft Maple. Its creamy white surface is artistically streaked with grey, brown, and sometimes reddish lines. These beautiful markings are made by the Ambrosia beetle, which bores into the tree and introduces a fungus that stains the wood around its tunnels.

This unique history means no two boards are ever alike. While it's softer than Hard Maple, with a Janka rating around 950 lbf, it's still perfectly suitable for decorative boxes, shelves, and small furniture.

For a comprehensive look, our deep dive into Ambrosia Maple lumber covers everything you need to know.

Workshop Tip: The beetle tunnels create small holes. For tabletops or food surfaces, filling these with a clear or coloured epoxy not only stabilizes the board but also turns these "flaws" into a celebrated design feature.

Cherry is a wood that ages with incredible grace. Freshly milled, its heartwood is a light pinkish-brown, but with exposure to light and air, it slowly deepens into a rich, reddish-brown patina. This transformation is one of the most rewarding parts of working with Cherry.

It has a Janka hardness of 950 lbf and is famous for its fine, straight grain and smooth texture. However, Cherry demands respect. It's notorious for showing burn marks from router bits or saw blades that aren't perfectly sharp and clean. To avoid this, use sharp tooling, maintain a steady feed rate, and consider taking lighter passes.

For a comprehensive look, our deep dive into Cherry Lumber covers everything you need to know.

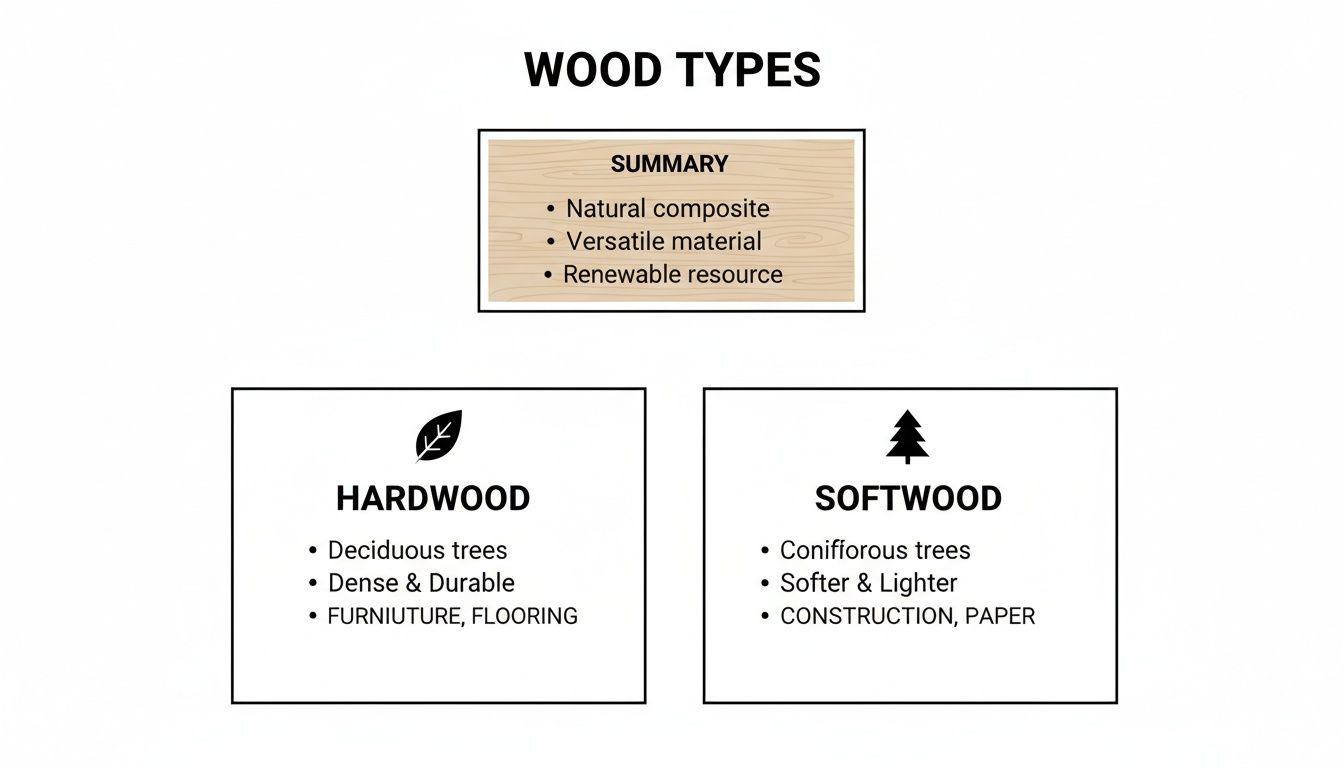

This infographic provides a quick comparison of the fundamental characteristics separating hardwoods from softwoods.

As you can see, hardwoods from deciduous trees are generally denser and used for durable goods like furniture, while softwoods from conifers are ideal for construction and lighter-duty applications.

To make things easier, here’s a quick-glance table comparing the domestic all-stars we've covered. Use it to find the perfect match for your next project based on looks, strength, and how it behaves in the shop.

| Wood Species | Appearance | Janka Hardness (lbf) | Workability | Common Uses |

|---|---|---|---|---|

| Black Walnut | Rich, dark brown with straight or figured grain | 1,010 | Excellent; cuts, sands, and finishes beautifully | Fine furniture, cabinetry, veneers, gunstocks |

| Ambrosia Maple | Creamy white with unique grey/brown streaks | ~750-900bf | Very good; easy to machine but mind the holes | Decorative boxes, turnings, small furniture |

| Cherry | Pinkish-brown that deepens to a rich reddish-brown | 950 | Good, but prone to burning with dull tools | Cabinets, fine furniture, musical instruments |

| Ash | Light, creamy colour with a bold, straight grain | 1,320 | Good; strong and bends well but has open pores | Tool handles, baseball bats, chairs, workbenches |

| Hard Maple | Uniform creamy white with a fine, subtle grain | 1,450 | Challenging; tough on tools, requires pre-drilling | Cutting boards, flooring, butcher blocks, workbenches |

Each of these woods has a place in the workshop. The key is knowing their strengths and playing to them.

Ash is a powerhouse hardwood known for its impressive strength-to-weight ratio. It was traditionally the wood of choice for baseball bats and tool handles for a reason—it can take a beating and flex without breaking. Its appearance is typically a light, creamy colour with a bold, straight grain pattern that's similar to Oak.

With a Janka hardness of 1,320 lbf, Ash is an excellent choice for projects that need durability, like workbench tops, chairs, and anything involving bent laminations. It machines well, but its open grain means you might need to use a grain filler before finishing if you want a perfectly smooth surface. Ash also takes stains beautifully, allowing you to mimic the look of other woods if you want.

When a project demands uncompromising durability, Hard Maple is the answer. With a Janka hardness of 1,450 lbf, it's one of the toughest domestic woods out there, making it the gold standard for cutting boards, butcher blocks, and flooring. Its colour is a uniform creamy white, and its grain is fine and subtle, giving it a clean, modern look.

This strength, however, makes it a challenge to work with. It’s tough on tool edges and needs sharp blades for clean cuts. Pre-drilling for screws is absolutely non-negotiable to prevent splitting. Still, for projects that need to be bombproof, nothing beats it.

Choosing between these champions depends entirely on your project's needs. Are you after the timeless elegance of Walnut, the unique artistry of Ambrosia Maple, the graceful aging of Cherry, the rugged utility of Ash, or the brute strength of Hard Maple? By understanding their individual personalities, you can confidently select the perfect partner for your next build.

When your project needs to go beyond the everyday and make a real statement, it’s time to step into the thrilling world of exotic woods. These species, sourced from all over the globe, are the true showstoppers of the lumber yard. They bring intense colours, dramatic grain patterns, and a sense of luxury that domestic woods just can't match.

Working with exotics is like adding a whole new set of vibrant paints to your artistic palette. They're most often used for accents, inlays, and smaller projects where their powerful appearance can truly shine without overwhelming a design. Think of a jewellery box with a Purpleheart lid or a cutting board with thin strips of Padauk and Wenge creating a stunning visual rhythm.

Padauk is famous for its breathtaking initial colour—a bright, fiery orange-red that seems almost unnatural. The moment you mill or sand it, the vibrancy is almost shocking. This initial burst of colour is part of its magic, but it's not permanent.

Over time, and with exposure to UV light, this brilliant orange gracefully mellows into a deep, rich reddish-brown. If you want to preserve that initial colour as long as possible, you’ll need to use a finish with a UV inhibitor. With a Janka hardness of around 1,970 lbf, it's a durable wood, but its coarse, open grain requires a bit of care during finishing to get a perfectly smooth surface.

Purpleheart performs a trick that never ceases to amaze woodworkers. When freshly cut, it often looks like a dull, grayish-brown board. But the real show begins when you expose it to sunlight. UV rays trigger a chemical reaction that transforms the wood into a spectacular, deep royal purple.

This incredible colour change is the wood's signature trait. It’s also incredibly dense and hard, with a Janka rating soaring to 2,520 lbf. This makes it very durable but also pretty tough on your tools. Sharp blades are an absolute must, and you should expect some resistance when cutting. Like Padauk, its brilliant colour will eventually darken to a brownish-purple, so a good UV-blocking finish is essential to keep it looking vibrant.

For a bold, contemporary look, few woods can compete with Wenge. This West African hardwood is nearly black, with fine, lighter-coloured lines that create a stark, graphic grain pattern. It has an almost architectural quality, making it a favourite for modern designs and dramatic accents.

Wenge is another dense species, boasting a Janka hardness of 1,930 lbf. Its grain is coarse and can be splintery, so wearing gloves while handling it is a really good idea. The dust from Wenge is also a known irritant for some people, making excellent dust collection and a respirator critical when you're working with it. Despite these challenges, its visual impact is undeniable.

A Note on Safety: Many exotic woods have oils and chemical compounds that can cause skin irritation or respiratory issues. Always research the specific wood you're using, wear a quality respirator, and ensure your workshop has good ventilation.

The stunning beauty of exotic woods comes with a few demands. Their density and hardness mean they are much tougher on your tools than domestic species. Expect to sharpen your blades more frequently and use slower feed rates to prevent burning.

Here are a few tips for success:

Exotic woods offer an incredible opportunity to elevate your projects from functional to unforgettable. To see how these species can fit into your next build, you can explore The Knotty Lumber Co.'s exotic wood selection and their uses for more ideas and inspiration.

The secret to a project you can be proud of is simple: right wood, right job. Sure, understanding the personality of each species is a great start, but the real magic happens when you pair a wood’s unique traits with what your project actually needs to do. This is where theory gets its hands dirty at the workbench.

Instead of just listing facts, we can start asking the important questions. Why do some woods shine in certain roles while others would fall flat? It all comes down to matching the properties of the wood to the function of the final piece. A stunning board used in the wrong place can lead to cracked joints and frustration, but a thoughtful choice guarantees your work will look great and last a lifetime.

Fine furniture is a balancing act between beauty, stability, and workability. The undisputed champion here is often Black Walnut. Its rich, chocolatey colour and cooperative nature make it a dream to shape, while its stability ensures that your intricate joinery stays tight through the shifting seasons.

Another fantastic option is Cherry, which ages with a grace that’s hard to beat, slowly developing a deep, warm patina that only gets better with time. For projects that need serious strength with a lighter, more modern feel, White Oak and Ash are brilliant contenders, prized for their durability and striking grain.

When it comes to surfaces that will handle food, the rules of the game change entirely. Three things are non-negotiable: hardness, porosity, and food safety. You need a wood that can take a beating from knives, won’t trap nasty bacteria, and is completely non-toxic.

This is where Hard Maple reigns supreme. Its tough Janka hardness of 1,450 lbf shrugs off daily chopping, and its closed-grain structure means its pores are tiny, locking out food particles and moisture. This makes it a breeze to clean and keep sanitary.

Other great choices for cutting boards include:

Working on a lathe brings a whole new set of demands. Woodturners are always on the hunt for woods that cut cleanly without a lot of tear-out, can hold crisp details, and have interesting grain or figure that pops as the piece takes shape.

Both domestic and exotic woods are popular for turning bowls, pens, and other rounded masterpieces. Ambrosia Maple is a huge favourite for the unique streaks and patterns caused by the Ambrosia beetle, which create truly one-of-a-kind bowls. Cherry is another classic, loved for how smoothly it cuts and the silky finish you can get right off the tool.

The passion for this craft is strong. The global woodworking market is valued at roughly $780 billion USD annually, showing just how dedicated woodworkers are. You can read more about the economic trends in craft woodworking to see for yourself.

Live edge slabs, which keep the natural, gnarled edge of the tree, are perfect for creating show-stopping tables, desks, and countertops. When you’re picking out a slab, you’re not just choosing a piece of wood; you’re choosing a centrepiece for a room.

Look for a slab that is relatively flat, with minimal twisting or cupping. Check for cracks, or "checks," which often appear at the ends of the board. While some small ones can be stabilized with epoxy and even add character, large, deep cracks can be a sign of structural problems. Most importantly, find a grain pattern and a natural edge that you absolutely love. Every slab is different, so take your time and find the one that speaks to you.

Walking into a proper lumberyard or browsing an online supplier for the first time can feel like learning a new language. You’re hit with terms like "4/4," "Select and Better," and "S4S," and it's easy to get overwhelmed. We're here to be your translator and take the mystery out of the buying process, so you can pick your boards with total confidence.

Getting these terms straight is the first step toward finding the right material for your project—and your budget. It’s the difference between ordering exactly what you need and ending up with wood that’s too thin, too thick, or needs way more work than you bargained for.

The most common point of confusion for new woodworkers is how hardwood thickness is measured. Instead of clean inches, you’ll see fractions like 4/4 (four-quarter), 5/4 (five-quarter), and 8/4 (eight-quarter). This system refers to the rough thickness of the wood in quarters of an inch, measured before it gets dried and surfaced.

This quarter system is the industry standard pretty much everywhere. In places like California, which has the highest employment level for woodworkers in the United States, suppliers regularly stock a huge range of thicknesses from 4/4 all the way up to 16/4 to serve everyone from big cabinet shops to small furniture makers. You can find more cool woodworking industry stats over on Gitnux.org.

Beyond thickness, you’ll need to decide how "finished" you want your boards to be. This choice directly impacts the tools you’ll need and how much prep time you'll spend in the shop.

Rough Sawn Lumber is exactly what it sounds like—wood straight from the sawmill. It has a fuzzy, coarse texture on all four sides and needs a jointer and planer to become flat and smooth. It’s more work, for sure, but it gives you total control over the final dimensions and is almost always more affordable.

Surfaced Lumber, on the other hand, has already been milled for you:

Learning to buy rough sawn lumber and mill it yourself is a game-changing skill for any serious woodworker. It doesn't just save you money; it guarantees your project parts are perfectly flat, straight, and square—which is the foundation of all quality work.

Finally, when you’re picking out individual boards, you have to become a bit of a detective. You’re hunting for clues that tell you about the board’s stability and character. Sight down the length and across the width of each board to spot these common issues:

While you want to dodge any major warping, not every "flaw" is a dealbreaker. Knots, wild grain patterns, and mineral streaks can add incredible character to a finished piece. Learning to tell the difference between a structural red flag and a beautiful feature is all part of the art of woodworking.

Once you’ve moved past the theory and are standing in front of a stack of lumber, the real questions start popping up. This is where the rubber meets the road. Below are some straight answers to the most common questions we hear from woodworkers, designed to give you clarity and confidence for your next project.

These FAQs tackle the practical challenges and curiosities that come up right after you've picked out your materials.

When you're building for the outdoors, your biggest enemies are moisture and insects, so you need a wood that’s ready for a fight. The best contenders are species with natural resistance to decay built right in. Teak, Cedar, and White Oak are all fantastic choices.

Teak is the undisputed king thanks to its high natural oil content, which makes it incredibly rot-resistant—but it also comes with a premium price tag. Cedar is a more budget-friendly softwood that naturally repels bugs and weathers the elements gracefully. And then there's White Oak, a domestic champion whose pores are plugged with natural structures called tyloses. This makes it highly water-resistant, a crucial trait its cousin, Red Oak, just doesn't have.

No matter which wood you pick, always protect your work with a quality exterior-grade finish to shield it from punishing sun and rain.

Absolutely! Mixing different wood species is one of the best ways to create stunning visual contrast in a piece. There's just one golden rule you have to respect: wood movement.

Every species expands and contracts at a different rate when humidity changes. If you’re building a large panel like a tabletop, it’s smart to pair woods with similar movement rates to stop your glue joints from failing down the road. For smaller decorative touches like inlays or accents, though, movement is far less of a worry. A timeless, can't-miss combination is the rich, dark tones of Walnut against the creamy brightness of Maple.

Think of the Janka rating as a wood's "dent resistance" score. It’s a simple measurement of how much force it takes to embed a steel ball into the wood. This number is your best friend for matching a wood's durability to how it'll be used.

For high-traffic surfaces that take a daily beating—like floors, countertops, or dining tables—you want a high Janka rating.

These woods are built to last. For projects that won't see much physical contact, like a decorative box or a bookshelf, a softer hardwood like Cherry (950 lbf) is more than tough enough. Just keep in mind that extremely hard woods can be tougher on your tools, dulling blades and bits much faster.

These terms describe how a log is cut into boards, and the method has a huge impact on a board's grain pattern, stability, and price.

Plain Sawn is the most common and affordable way to mill lumber. It produces that classic, wavy "cathedral" grain pattern but is also the most likely to cup or warp. Quarter Sawn boards are cut so the growth rings are nearly perpendicular to the face, giving you a straight, linear grain and excellent stability. Rift Sawn offers the straightest grain and the absolute best stability, making it the top choice for things like furniture legs where staying perfectly straight is critical.

At The Knotty Lumber Co., we stock a huge range of domestic and exotic hardwoods to answer the call of any project, from a simple cutting board to fine furniture. Explore our curated selection of lumber, live edge slabs, and project-ready bundles to find the perfect material for your next build. Visit us at The Knotty Lumber Co. to get started.